PIND

For reliability testing of all types of Ics / Relays / switches and hybrid electronics , detect the particles with our PIND Felix system.

For over fifty years, Spectral Dynamics Inc. has given users simple, reliable and inexpensive tools to perform Particle Impact Noise Detection (PIND) testing to increase the reliability of electronic components.

The PIND FelixTM is the most advanced system available. Combining sensors that monitor and display the shaker motion with computer generated control to correct for changes in test conditions, the PIND FelixTM test system generates accurate and repeatable test conditions while meeting or exceeding all of the globally recognized test specifications.. The PIND FelixTM is truly a technology that the industry has been waiting for.

To provide always the best to our customers, Spectral Dynamics Inc decided in 2019 to discontinue the manufacturing, marketing and sale of the Spectral Dynamics former PIND Model 4511. Any representation by others that a similar or like product with the same features, functions or model number advertised or available for sale by the Spectral Dynamics USA or an affiliate of Spectral Dynamics is an unauthorized representation by such parties.

Support and services are still available for all Spectral Dynamics PIND systems including PIND FelixTM, PIND 4511 and PIND 4501 in our offices in the USA and France (for Europe).

The PIND Felix™ System has been designed to detect loose particles in electronic components. The system is programmable to provide speedy and precise automatic testing in accordance with the various standards. The interactive interface allows the operator to enter the desired stored test sequence and to control the test with ease.

The solution is completely designed by Spectral Dynamics. As this system is designed, manufactured, and built by Spectral Dynamics the quality of both components and build is controlled.

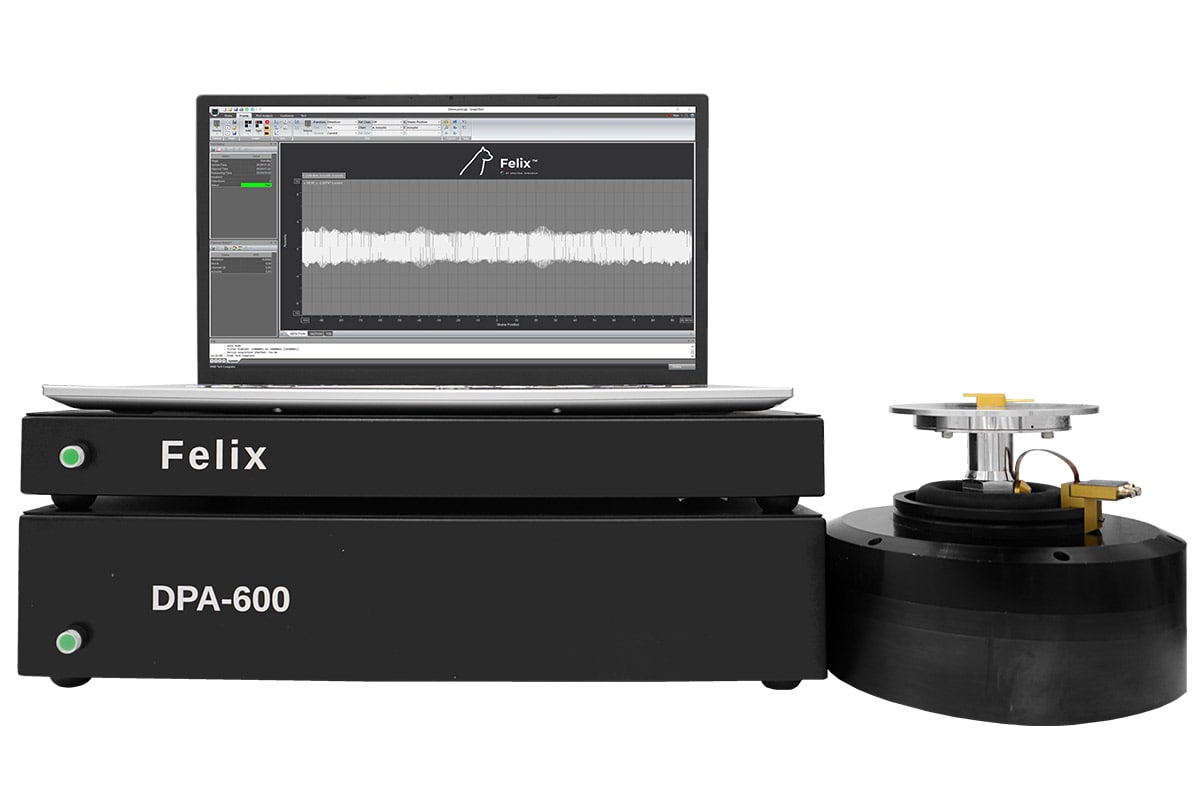

The PIND FelixTM is composed of:

- Precision Shaker with a crystal sensor system

- DPA600 digital Amplifier and FelixTM controller system

- Computer system with FelixTM software

- STU (Sensitivity Test Unit) unit to verify that the system is functional.

The system performs five major tasks:

- Vibrate a test article

- Shock a test article

- Detect any particle contaminants within the cavity

- Display the detected impact signals created by the loose particles

- Record the motion environment and the acoustic signals detected

The controller driven shaker provides shock and vibration motion of the test article. The impact sensor detects signals generated by a loose particle within the cavity of the test article, converts the physical energy into electrical energy which is passed through the cables to the amplifier and detection circuitry within the controller. Indication of the presence of loose particle detection occurs when the Acoustic Impact signal exceeds the programmed threshold limit.

Key features of the PIND FelixTM solution:

- Sensors

Depending of the test, Spectral Dynamics can supply single crystal or multiple crystal sensors. All our sensors have a complete Faraday shield around each crystal to protect the sensor from unwanted stray electrical signals. The embedded accelerometer allows monitoring and display of the actual shaker motion with computer analysis and correction for any changes in test conditions.

- Shaker

The unique shaker creates accurate “Active Shocks” with adjustable shock levels by controlling the velocity of the shaker head and correcting for device differences prior to impact

- Advanced software (Windows 10)

PIND FelixTM software allows for data collection of the vibration, shock, and acoustic channels. Each type of signal can be replayed for more in depth understanding of the interactions between the acoustic noise and the motion environment. Visual and audio particle detection are integrated to easily control your component. The software is compatible with tools like Microsoft Office. Reports for presentation or printing are simple to do.

- PIND testing according to international standards and internal process

The PIND FelixTM easily exceeds the requirements of all military standards for PIND testing (U.S. MIL-STD-883, 750, 202,39016D). It is also fully programmable to your own specifications if so required.

Our high frequency acoustic test monitors for loose particles moving inside high reliability internal cavity electronic components such as relays, transistors, integrated circuits, and switches – particles that have the potential of causing short circuits and serious malfunctions in system operations.

A shaker is used as a linear motor to excite loose particles to move within the component cavity. Upon striking the lid of the cavity, some of the particle kinetic energy is converted to a wide band acoustic pressure wave that travels through the lid, through the attachment media and onto the top surface of the Impact Detection Sensor.

The acoustic wave is detected by the sensitive ultrasonic crystal or crystals within the sensor and is converted into an electrical signal. To keep the particle moving, a very accurate shock, generated internal to the shaker and controlled by the computer, monitoring the motion of the sensor, is employed.

In the PIND Test, the particles are never measured directly. As the loose particles are placed in motion with a vibration, shock, the system then detects the impacts of those particles as they contact the lid of the cavity.

To learn more about the application, download our brochure.

Shaker options

4501-M230 Heavy duty vibration and shock shaker

4501-M230R Heavy duty shaker with wide pulse anvil included

4501-M230D Heavy duty shaker with two magnets

Sensor options

100-S140C/A Single crystal sensor – 22 mm

100-S140C/AL Single crystal sensor – 50 mm

100-3S155-60 Multiple crystal sensor – 60 mm – Three crystals

100-5S155-4 Multiple crystal sensor – 100 mm – Five crystals (1 in center with 4 mounted in a square at 50 mm)

Mounting options for components

There are two mounting mediums of the component on sensor:

- Acoustic gel couplant

The couplant provides both excellent acoustic transmission as well as limited adhesion for keeping the device in good contact with the device under test.

- Double sticky dots

Spectral Dynamics provides dots in several sizes. The doubled-sided dots provide excellent adhesion and good acoustic transmission. The transmissibility of the dot is less than the couplant by about 10% (1 dB).

Other options

Remote control box

The USB box for remote control can be used by the operator to:

- Load a test from the setup library

- Start the current or selected test

Shaker support

Need to isolate the shaker from your desk? Our team developed a dedicated support to perform your test anywhere.

Transport case